Brighteco

Home What is Circular Economy ? Our project The encyclopedia Newsletter Langues Brighteco Web : brighteco.se Contact : info@brighteco.se Localisation : Sweden Date of meeting : 15 june 2023 Maturity of the projet : Intermediate EFC Recycling Brighteco is a Swedish start-up founded just over 10 years ago by Joel Smedberg, after he became aware of his material footprint and global impact on the planet. His desire to contribute to the creation of new ways of producing and consuming led him to start his own company, whose purpose is to sell light as a service. Lighting as a service: from identifying user needs to installing luminaires The sale of light as a service is very different from the simple sale of a luminaire to a customer. That’s why the first question we ask our customers is : “Do you really need this ? Are you prepared to take responsibility for these resources ?”. It may seem far removed from a company’s sales objectives, but for Joel, asking these questions builds trust between them and their customers, and also shows that they are honest in their purpose to reduce their material and carbon footprint. “Basically, selling light as a service means selling the function that you need at any particular time.” If the answer to these questions is yes, then the next step is to go on site to analyze the space in question, identify the needs of the users of these spaces, what their schedule will be, will they be sitting or standing, etc. They can install the right luminaires more efficiently and more flexibly by asking what light is needed, for what and for whom. In fact, if the Brighteco team knows whether the space in question will change in 5 or 10 years , they will design more flexible luminaires. Once the luminaires have been installed, Brighteco’s teams provide long-term customer support to ensure that the luminaires continue to meet user expectations. Source image : brighteco.se A circular business model The very design of the luminaires is part of a recycling and eco-design approach. The luminaires are made from old flat screens. These screens contain rare and very precious metals such as indium, for which there are very few mines in the world, so a second life is essential. However, repurposing old flat screens comes with a cost, and that’s why light as a service is born. Rather than investing heavily in luminaires that are much more expensive yet recycled but equivalent in quality to those on the market, customers pay a small sum each month for luminaires that are perfectly adapted to their needs, modular over time and which will therefore have a longer lifespan. For very good quality light, such as in schools, Joel explains that you should expect to pay between 90 and 95 SEK/m²/year, or between €7 and €8/m²/year, but for industrial buildings with very different needs, the price can come down very quickly. Brighteco’s luminaires are therefore designed to be as simple as possible, so that they can be easily repaired by local electricians, converted from a decorative luminaire to a wall or ceiling luminaire, the brightness can be adjusted, and so on. What’s more, they are designed to be easy to remove and not to lock customers in, so they are free to change their lighting supplier if they decide to. Brighteco is backed by a research programme that has calculated a 97% material savings rate in terms of lighting over the lifetime of an office (30-40 years). Committed local municipalities The start-up’s main customers are municipalities, which, according to Joel, are driving the ecological transition in Sweden. They often come with very concrete issues relating to the cost of investing in new lighting but also with a desire to address environmental issues and reduce their material footprint. Buying light as a service therefore meets their needs perfectly. For Joel, what could really change the game and help them to develop would be to introduce an annual resource consumption budget for each municipality : this would encourage everyone to take care of the things around them and make a lot of sense given the depletion of natural resources. Back to encyclopedia Our other articles on the same topics Fritidsbanken Mifactori Madaster Les Pailles de Provence Newsletter CirculAgronomie Facebook Youtube Linkedin Instagram Copyright CirculAgronomie 2020

Fritidsbanken

Home What is Circular Economy ? Our project The encyclopedia Newsletter Langues Fritidsbanken Web : fritidsbanken.se Contact : henric@fritidsbanken.se Localisation : Sweden Date of meeting : 12 june 2023 Maturity of the projet : Mature Functional economy Reuse Sports Borrow sports items Fritidsbanken – “free time bank” in English – is a Swedish NGO founded almost 10 years ago to promote the development of sports libraries throughout Sweden. We had the opportunity to meet Henric, Fritidsbanken Sverige’s communications manager, and Edvin, an employee at Fritidsbanken Karlstad, one of the country’s largest sports libraries. “We have three pillars at Fritidsbanken: basically all the items have been donated, everything is free and anyone can borrow them.” Henric Byström, Head of Communications at Fritidsbanken Sverige From a simple idea to a national concept The story of Fritidsbanken can be told most authentically by Henric. It was his wife, Carina Haak, who came up with the idea 10 years ago. She found it strange that people could borrow books from municipal libraries but not sports equipment. What’s more, as the deacon of the small municipality of Forshaga, she was in regular contact with single mothers in financial difficulty who couldn’t provide their children with the equipment they needed for winter sports day at school. So it was in autumn 2012 that the first equipment began to be collected in the municipality of Forshaga and the first Fritidsbank officially opened in January 2013, with some 200 items. Ten years later, there are 127 Fritidsbanken across the country with almost 500,000 items of sports equipment available for use. These local Fritidsbanken are 90% managed by municipalities that have requested them, with the remaining 10% managed by sports associations, non profit organizations or charities. According to Henric and Edvin, in view of the ever-increasing demand, they will most likely all be managed by municipalities within a few years, with the latter putting them on the political agenda. “The staff who work here are paid by the municipality because it was decided that this was an initiative in which money should be invested.” Edwyn – employee at Fritidsbank Karlstad All the municipalities and associations that run local Fritidsbanken are members of the NGO Fritidsbanken Sverige, which receives funding from the Swedish National Sports Confederation, the Swedish Central Association for the Promotion of Sport, the Värmland region, etc. Where do the items come from ? Basically all the equipment found in all the Fritidsbanken in Sweden is donated by private individuals, who are encouraged by the NGO to part with it if they are not using it. Sometimes companies, sport clubs and other organizations donate equipment as well. “If you’re not using it, someone else could.” Henric, Head of Communications at Fritidsbanken Sverige Donations are collected directly at the Fritidsbanken and in some large towns, such as Karlstad, there are drop-off points more centrally located in the town so that everyone can donate without having to travel too far. Once an item has been donated, it is put into the digital system almost immediately if it is in good condition and there are no security concerns. To open a new Fritidsbank, it’s recommended to have at least 1,000 pieces of equipment to ensure a complete offer and also to give a ‘wow’ feeling, as Edwyn describes it, which makes people want to buy from such places. That’s why establishments that have been around for longer donate some of their equipment to new establishments that sometimes find it difficult to establish themselves. Who can borrow and how ? As the pillars of Fritidsbanken state: everything is free and anyone can borrow. Edwyn explains that new visitors are always quite confused when they are told that they don’t need a membership, ID card or bank card. Anyone can come and borrow as much equipment as they like and the only thing they need to leave is a name and a phone number or email. In this way, even young children can borrow equipment on their own, simply by leaving the telephone number of one of their parents. After two weeks’ use, anyone can return the item, and it’s as simple as that. “It’s so simple it’s almost deceptively simple.” Edwyn – employee at Fritidsbank Karlstad “We trust and hope that people will take what they like here, use it appropriately and come back with what they took. And it works 99% of the time.” Henric, Head of Communications at Fritidsbanken Sverige According to them, this way of proceeding encourages people to continue coming and it builds a relationship of mutual trust. Henric tells us about a man from Syria who came to borrow equipment and was shocked not to have to show his identity card. It was very important for him because it was “the first time since he arrived in Sweden that he didn’t have to prove his identity, he was simply trusted”. Why use Fritidsbanken ? There are many ecological and economic reasons to borrow equipment from a Fritidsbank. One of them is to extend the life span of objects that would otherwise have been thrown away, but also to prevent the unnecessary production of new objects. “Many people think it’s for the poor, for those who can’t afford to buy their own things. This is the case if you think that buying your own items is the right thing to do. If you only use an item for one day a year, it doesn’t make much sense to buy it and store it for 364 days.” Henric, Head of Communications at Fritidsbanken Sverige Edvin explains that the aim of Fritidsbanken is not to take everyone’s equipment and make it available collectively. The idea is to allow everyone to discover different activities and to enjoy one so much that you end up feeling the need to buy your own equipment. “Let’s say someone wants to try ice skating, we have different sizes of skates that they can use over several weeks, then borrow new ones, and maybe in

Mifactori

Home What is Circular Economy ? Our project The encyclopedia Newsletter Langues Mifactori Web : https://mifactori.de/ Contact : hello@mifactori.de Localisation : Germany Date of meeting : 10 May 2023 Maturity of the projet : Mature Eco-design Recycling Open source A design studio Mifactori is a studio for open circular design based in Berlin. For more than 10 years they have been rethinking design in every possible way: what kind of materials, assembled in what way, for what purpose, produced where ? We had the chance to meet Lars Zimmermann, artist, designer and founder of Mifactori. What is circular design ? Linear design is about extracting resources, turning them into products, using them and then throwing them away, so new resources have to be found to produce them again. In contrast, circular design implements loops based on circular principles such as the 9 R’s : rethink, refuse, reduce, reuse, refurbish, repair, repurpose, rot and recycle. So circular design is about trying to design around these loops : design something that is easy to repair, easy to repurpose, easy to recycle nearby… What is open design ? The idea of open design was born and became popular in the 2000s when the internet really hit the mainstream. Suddenly anyone could create something and share it with the world. Something that in the old world only big companies could do. Many people thought it was possible to apply this to the world of physical objects. Open design is about supporting global making and remaking through easy-to-make, well-documented designs and open licences. Based on this idea, open design is design made in such a way that any designer or non-designer can participate in making and designing new objects : they have to be easy to make, easy to understand and inclusive. “If everyone can understand how to reuse something then more people will reuse it, if more people understand how an object is made, more people can repair it.” Trikka : a platform for open circular design Today’s products are mostly made up of parts that are disposable and custom-made, meaning they can only be used in one particular product. So if one part breaks, the whole product is lost and it’s very difficult to reuse or repair. So why not design products using standard parts that are very easy to make and are also reusable, meaning the same part can work in many different products ? Inspired by Lego and Meccano, the Trikka system was created and all parts in this system are based on the same grid : evenly spaced holes in the parts so they always fit together. The Trikka platform now has 40 products and a catalogue of 120 parts, each of which belongs to at least two different products. Source image : Mifactori So if you have a chair from the Trikka system and a part of it is part of three other products, when the chair doesn’t suit you anymore, you can reuse it in another product which greatly extends the life of each part. What’s more, any designer can come to the platform and find the documentation for a part they like, make it and use it in one of their own designs, and they can also a add new parts to the catalogue : this is open design. With this concept, the catalogue also grows over time and you can have a part that is part of two products one year and two years later, the same part is part of six different products ! Source image : Mifactori What are the side-benefits of such a concept ? There are many very interesting aspects to this Trikka system, both circular and open source. The first one, as Lars explained to us, is that this system could work without centralised manufacturing and boost local makers. For example, if you see a chair you like on the Trikka platform, but you can’t buy it because there’s no manufacturer near you, you’re invited to find your local carpenter, call them and they can go to the website and find perfect documentation of all the parts to make the chair. In this way it could also stimulate local crafters to create more with modularity and stimulate a real loop locally. Another aspect they have with the Trikka system is tolerance : they try to come up with parts that can be made from different materials and sizes and still work together. This really encourages the use of local resources, the reuse of leftover materials that don’t necessarily have the right shape and form, but can still fit. Less precision in materials and sizes also allows for simpler hand tools, making it more affordable. Finally, one of the most important side effects, in our opinion, is that it stimulates creativity. As customers, we’re not used to being asked to redesign or rethink products in order to create others. Seeing products not as one piece, but as a multitude of parts that can be taken apart and reused in different ways, allows the user or designer to create and imagine more. Back to encyclopedia Our other articles on the same topics Madaster Les Pailles de Provence La Fumainerie Toopi Organics Newsletter CirculAgronomie Facebook Youtube Linkedin Instagram Copyright CirculAgronomie 2020

Madaster

Home What is Circular Economy ? Our project The encyclopedia Newsletter Langues Madaster Web : https://madaster.com/ Contact : info@madaster.com Localisation : Netherlands, Switzerland, Germany, Belgium, Norway, Austria Date of meeting : 20 april 2023 Maturity of the projet : Mature Eco-design Recycling Digitalization Eliminate waste from the construction sector Created six years ago, Madaster is an international scale-up steering the construction sector towards a circular economy. Their purpose is to eliminate waste from the construction sector through digitalization and with the spreading of a new concept : the material passport. Born in the Netherlands, currently active in 5 further countries – Switzerland, Germany, Belgium, Norway and Austria – and growing, they are at the forefront of the transition toward a circular economy in one of the most waste-intensive industry sectors. We had the chance to meet Martijn Oostenrijk, one of the co-founder of Madaster and now managing director of the company. The construction sector : CO2-, resource- & waste-intensive The construction sector creates more than 247 millions of tons of waste each year in France, making this sector responsible for more than 70% of all waste generated [1]. In the Netherlands, Martijn explains that this statement is not much different : in the linear system, with a take-make-waste point of view, 40% of the materials end up as degenerated stuff and lost for future use. Moreover, carbon dioxide emissions linked to the construction sector reached 10 Gt in 2021, for a global total of 37 Gt : almost a third of all global emissions [2]. Those numbers make it clear that the construction sector really is a big part of the climate and waste issues. However it is not new information that the building industry is not the greener one, so why is it still so ? For Martijn, it is mainly due to the construction sector being very conservative and late in the digital transformation, in combination with the fact that finance still rules our world and financial people don’t understand that materials are valuable in essence. Facing those challenges, Thomas Rau, a pioneering Dutch architect and author of the book “Material Matters”, approached Martijn Oostenrijk and Pablo van den Bosch, then working in the finance industry, to help him explain that circularity comes with financial benefits and value : Madaster was born. Image source : RAU, Triodos Bank “Ok this makes a difference, this is important, this is urgent and here we can make change” What is Madaster ? Madaster is an online platform, and like the land register, one can register all materials and products in their built environment, whether it is real estate or infrastructures. Once those materials are registered, they are provided with an identity. In the end, the aim is to extend this platform at a major scale so that it could be able to register any objects anywhere in the world. “Giving them an identity means that we can make conscious decisions about their future use instead of degrading those materials into a waste stream.” The importance of digitalization The construction sector has certain industry standards all architects, construction companies and engineers work with. Among those standards is something called the Building Information Management or BIM, that is the digitalization of a building. It contains all the different materials and products that are assembled in the product. Along with that is the Environmental Product Declaration (EPD) : defined by the ISO, it enables each company producing a product to quantify environmental information on the life cycle of this product to enable comparisons between products fulfilling the same function. Each year, legislation increases the demand for such declarations. Hence, combining the BIM where “everything you can imagine in a building is captured” with the EPD of the products inside the building, enriching it with all kinds of environmental and financial data from trustworthy sources, Madaster creates many precious environmental and financial indicators for their clients, such as circularity index, detachability, embodied carbon or financial residual value. The circularity index Based on the Ellen Mc Arthur methodology, the circularity index is constructed based on three stages : the development stage, the use stage and the end-of-life stage. Within those tree stages, if more existing materials are used instead of virgin, that’s a plus in the development stage ; if the construction and the materials used during the construction phase lead up to a longer lifespan than the average, then that’s a plus, and if it was constructed in a way that it can be detached from the building for reuse, that’s a plus. The combination of those three stages leads to a circularity index between 0 and 100 and the score is penalized if information is missing. The financial residual value It is the value of a building at the end of its life : what materials can be reused, what’s the cost of reusing these materials ? Current and historical prices of each material in the building have been looked upon to create a line toward and guess their price in the future. Then, deducting the cost of removing, transporting and processing these materials for reuse, we can have the real financial residual value of a building. If materials are assembled in a way that they are easily detachable, it will lower the cost of processing it and increase the financial residual value of a building. “When we calculate the residual value of materials in a building, we want it to be really high because that incentify the user to get that steel bar out and sell it for reuse.” Whom is Madaster made for ? As a self-service platform, everyone can start working with Madaster simply by registering to an annual subscription : 900 €/year for businesses and 20€/year for private persons. The entire value chain of construction is invited to use Madaster. From the asset owners (governmental body, major investor, house owners) to the building team and finally the accelerators such as banks, insurance companies and so on. The latter will

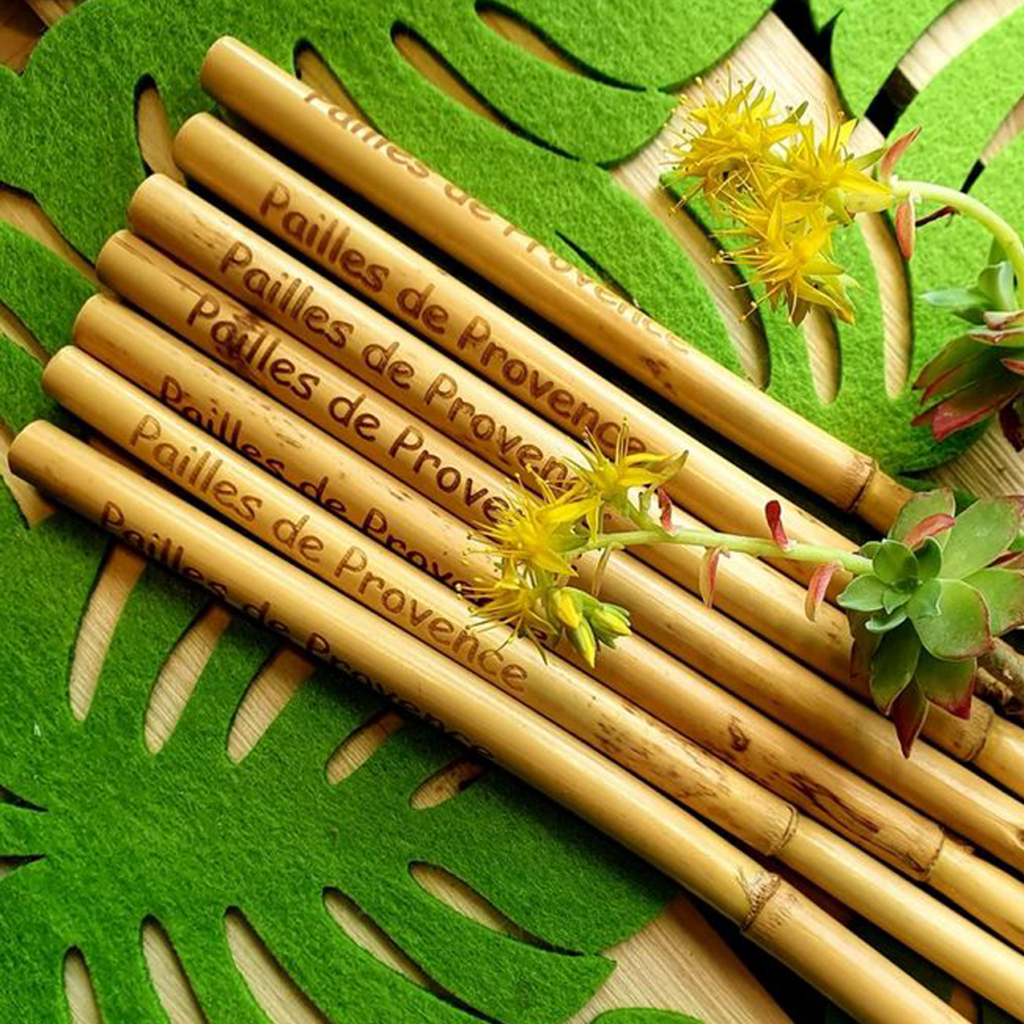

Les Pailles de Provence

Les Pailles de Provence Recycling FRANCE Web: Les pailles de Provence Contact: Les pailles de Provence Localisation: Cogolin (83) Sector: Recycling Date of creation: 2020 Date of meeting: 10/05-/2021 Maturity of the projet: Mature OVERVIEW Since 1966, the Rigotti company, located in Cogolin in the Gulf of Saint Tropez, has been producing reeds for wind instruments (clarinet, saxophone…). These reeds are made from Provence cane, grown by the company itself. When the cane is harvested, 40% of the stalk remains in the field where it decomposes. A small part of the cane is used for the manufacture of the reeds. The rest of the cane is used as compost. It was while watching a report on the ban on plastic straws in France that Daniel Rigotti had the idea of using the cane residues to make straws. Indeed, some parts of the cane already look like straw. There are already straws made of bamboo from Asian countries. Daniel Rigotti wants to produce a French product and to limit transport distances. The pieces of cane intended for the straws are cut to the right size and sanded. The straws are organically grown and quality tests (for food contact) are underway. The packaging is currently being finalised and will allow the straws to be sold in organic shops and interested supermarkets. These straws are manufactured and transformed (cutting + engraving) by the Rigotti company and are then sold by the company Les Pailles de Provences, which handles the commercial side.Les Pailles de Provences was launched in 2020 but the health context made the launch complicated. The main customers are currently restaurant owners or event organisers (weddings, etc.). Back to the encyclopedia Newsletter CirculAgronomie Subscribe Facebook Youtube Linkedin Instagram Legal information Copyright CirculAgronomie 2020

La Fumainerie

La fumainerie Industrial and territorial ecology Recycling FRANCE Web: https://www.lafumainerie.com/ Contact: lafumainerie@zaclys.net Localisation: Mérignac (33) Sector: Recycling Date of creation: 2019 Date of meeting : 22/04/2021 Maturity of the project: experimentation A citizens’ association that accompanies urban territories in the transition of their food-excretion system Overview History of the project La Fumainerie [1] is an association under the law of 1901 founded in February 2019, located in Bordeaux. The association has given itself 2 years to carry out an experiment which aims to show that it is possible to re-circulate our excretory feeding system. The aim of this circularisation is to valorise the nutrients present in our excreta and to participate in the effort to preserve our water resources. The objectives of the experiment are to highlight the benefits of a more circular and ecological sanitation system and to measure the level of social accessibility of a profound change in our sanitation methods. Ecological sanitation is a circular excreta management process. It takes into account : conditioning, which corresponds to the storage of the material in a closed space. sanitation, i.e. the hygienisation of the material. There are soft methods (e.g. composting) and active methods (e.g. pyrolysis). Whatever process is chosen, the safety of people and the environment must be promoted above all. recovery and recycling of materials. We must favour a return to the soil of the materials. The association sets up dry toilets in private homes (separation of urine and faeces at the source), collects urine and then seeks or develops adapted urine and faecal matter recovery channels in partnership with local public and private players. The ultimate goal is not the generalisation of a single solution, but rather a collective awareness and deployment of material extraction solutions and management systems that adapt to needs. Key numbers 30 urine collection sites since September 2021 28 sites in private homes 3 sites in places open to the public (a co-working wood, a third place and an association of animation and artistic diffusion) a total of 86 co-producers who use the toilets Pilars of circular economy Industrial and territorial ecology through the development of a local urine and faecal matter recovery system and cooperation between players (La Fumainerie, which works with Toopie to recover urine, Recup Bokashi Aquitaine for the co-composting of organic matter and with Un petit coin de paradis to design adapted separative toilets). Recycling by removing urine and faeces from the status of humanity’s ultimate waste. How the project works To listen to Ambre Diazabakana present the project, you can watch the video at the bottom of the article! 1. The composition of the association La Fumainerie is an association under the French law of 1901 which is composed as follows A collegiate management team of 6 people, including some co-producers of the network. They are citizens of the Bordeaux metropolis who wish to become actors and decision-makers in their sanitation 2 employees, including a coordinator and a network coordinator, supported by a civic service employee (present for 6 months in the association). They are all in charge of urine collection but also of the bokashi (pooling of human resources). The membership, numbering 99 in 2020. The association collects urine from 30 sites which represents about 86 people, 1097 kg of urine and 345 kg of faeces collected in April 2021 and 5200 litres of urine collected since September and 1700 kg of faeces collected since September. Les partenaires techniques de l’association sont : Un petit coin de Paradis a producer of dry toilets that has developed a model adapted to the activity of the Fumainerie. Recup Bokashi Aquitaine with whom the association shares human and material resources for the collection and composting of materials Toopi Organics, which recovers urine for use as biostimulants. An industrial composting platform (PENA Environnement). As the association is in an experimental phase, PENA Environnement has agreed to charge only for the collection of the bins (€60 per tonne for transport) and not for the cost of processing the material (between €90 and €100 per tonne). 2. Suitable collectors The first issue in excreta recovery is the method of collection. Source separation avoids contamination of urine (which contains very few pathogens) by faeces. Devices already exist on the market: dry male or female urinals and “separating” toilets: urine flows forward by gravity faeces and toilet paper are collected at the back in a suitable container. However, the collectors already on the market were not adapted to the urine collection method developed by La Fumainerie. Collection is carried out at home using electrically assisted cargo bikes. The containers were not suitable for this mode of transport. For urine, for example, the bins did not have a watertight closing system. La Fumainerie therefore worked in partnership with Une petit coin de Paradis to develop separate toilets adapted to their mode of collection. To combat bad odours, inputs are added to the various containers: lactic acid at the bottom of the urine containers to stabilise the urea. This stabilisation of urea prevents its degradation into ammonia, the molecule responsible for bad odours.. sawdust in the faeces tanks to allow faster drying, to cover the material to prevent the invasion of pests (flies) and therefore to avoid bad odours. 3. Installation issues The implementation of such an ecological sanitation system requires a rethinking of toilet design: the need for a well ventilated or at least air-conditioned space. Instead of putting the air-conditioning up, it makes sense to install the air-conditioning at the bottom of the room in order to draw the bad smells downwards. rethink the lighting system: overhead lighting makes the use of toilets by viewing materials unattractive. 4. Collection from co-producers Initially, the starting point for collections was Mérignac. However, this organisation wasted time, due to the time spent on the roads, and increased the risk of road accidents. La Fumainerie therefore set up neighbourhood houses with Recup Bokashi Aquitaine in the city centre of Bordeaux to optimise collections, supported by

Toopi Organics

Toopi Organics Sustainable supply Eco-design Industrial and territorial ecology Recycling FRANCE Web : https://toopi-organics.com/ Contact: contact@toopi-organics.com Localisation: Loupiac-de-la-Réole (33) Sector: Recycling Date of creation: 2019 Date of meeting : 21/04/021 Maturity of the project : Mature Valorise human urine into products for agriculture and industry. Overview History of the project Toopi Organics was created in 2019 after a meeting between three entrepreneurs. Matthieu Préel, manager of the company « Un Petit coin de Paradis » was daily confronted with the problem of recycling human urine. Through his dry toilet rental business, he has to pay to dispose of the urine he has collected. Michael Roes, founder of a biological fertiliser company, and Pierre Huguier, a doctor in soil ecotoxicology, have therefore developed a microbiological process to recycle urine into products for agriculture and industry. The company is currently developing its first product and hopes to have it on the market in the first half of 2022. Key numbers 1L of urine = 1L of finished product Goal to collect 1% of the urine generated in France Pilars of circular economy Sustainable supply Eco-design by developing a low-tech system for urine recovery. Industrial and territorial ecology through the linking of different actors in the same territory. Upstream actors for the collection of urine and downstream actors for whom the products are intended. Recycling of urine and its use as an agricultural input. How the project works ? To listen to Benjamin present the project, you can watch the video at the bottom of the article! 1. Urine, from waste to resource? Urine is actually seen as a waste product. It is eliminated via toilets and then treated with all sewage in purification plants. However, this current model has its limits. It poses problems for the sustainable management of water resources. On average, a flush consumes 9 litres of drinking water, which represents 10,000 litres per year and per person, or 20% of our annual water consumption. When water is treated in wastewater treatment plants, ⅔ of the nitrogen is released into the air and ⅓ into the water. Only 5% of the nitrogen in sewage sludge is recycled, which means that most of the nitrogen ends up in the wastewater. It should be noted that all the nitrogen consumed by humans is excreted, which represents 5 kg of nitrogen per person in one year. Because of its high nitrogen content, sewage sludge is the cause of eutrophication. Urine is mainly composed of water and contains a triptych of minerals that are very interesting for agriculture: the NPK triptych. Urine contains a significant concentration of nitrogen (N), phosphorus (P) and potassium (K), which play an important role in soil fertilisation. Translated with www.DeepL.com/Translator (free version) 2. From collection to urine recovery Toopi Organics sees itself as the final player in the urine recovery chain. One of the challenges is to collect a significant quantity of high-quality urine. Urine collection is currently done locally and is set up with various partners: WCLoc, local partners: WCLoc, local authorities via the installation of dry urinals (male and female) in Langon and La Réole and medical analysis laboratories in Gironde. Other collection sites are being considered to recover large volumes: establishments open to the public (ERP), and toilets at motorway or construction site rest areas, for example. To ensure that the urine is of good quality, the Toopi Organics team adds lactic acid to the urine collection tanks. Lactic acid stabilises the urine and the degradation of urea into ammonia, a molecule that is responsible, among other things, for unpleasant odours. To ensure that the urine is of good quality, the collectors must carry out the following checks before shipping: pH test at different depths of the tank, colour test, etc. If all the conditions are correct 24 hours before shipping, the urine can be shipped. To ensure that the urine is of good quality, the collectors must carry out the following checks before shipping. If all the conditions are correct 24 hours before shipping, the urine can be shipped. Further tests are carried out on receipt of the product. If the urine is not of the expected quality, it is sent to a treatment plant for processing. The recovery of urine into biostimulant is done in a low-tech process. A bacterial strain of interest and a carbon source are inoculated into the urine, which is kept at 30 to 40°C. This low-tech process ultimately makes it possible to offer a product whose purchase cost is much lower than the current market price. Titre de va-et-vient test test Sustainable developement approach Environemental benefits Urine reclamation has a number of advantages as it leaves the water treatment process. Firstly, the use of waterless urinals, which are necessary for urine recovery, enables a more sustainable management of water resources. In addition, taking urine out of the water cycle can solve the problem of its disposal in wastewater treatment plants. It is still complicated to treat urine properly, particularly because of its high nitrogen concentration, which is responsible for eutrophication. Finally, the urine recovery process is low-tech, consuming very little energy. Economical benefits The combination of the use of human urine and this low-tech process makes it possible to offer farmers a much cheaper product. Reproductibility and development perspectives Development perspectives Toopi Organics expects to have its first product on the market in the first half of 2022. The processing capacity of the current plant is 400,000 litres, the next one will have a capacity of 2 million litres. Toopi Organics aims to develop its model throughout the country with the installation of processing sites in areas with more than 1 million litres of collection. Harvesting will take place within a 200km radius of the plant to avoid transport costs and pollution. Toopi Organics wants to diversify its product range over the years. Back to the encyclopedia Newsletter CirculAgronomie Subscribe Facebook Youtube Linkedin Instagram Legal information Copyright CirculAgronomie 2020

Restovalor

Restovalor Recycling FRANCE Web: https://www.restovalor.fr/ Contact: contact@restovalor.fr Localisation: Cénon (33) Sector: Recyclage Date of creation: 2020 Date of meeting : 20/04/2021 Maturity of the project : Mature Collection and recovery of bio-waste in the Bordeaux metropolitan area Overview Summary of the project Restovalor, based in Cenon on the outskirts of Bordeaux, offers a customized collection service for biowaste generated by the restaurant industry in the Bordeaux area. The company also offers specific containers and adapted collections to recover this bio-waste into biogas and compost through a methanization process. Key numbers 100 clients 150 tons of biowaste collected per month 2,000 tons of biowaste per year 10% of sorting refusals Pillar of circular economy Recycling by offering a tailor-made recovery loop to bio-waste producers. This collection is adapted to the size of the producer. Project functioning To listen to Daniel Folz present the project, you can watch the video at the bottom of the article! Founded by three partners in 2020, Restovalor offers a bio-waste collection service that allows it to be included in a recovery loop. 1. Law on Energy Transition (17/08/2015) The Energy Transition Law [1] of 17/08/2015, one of the 6 objectives of which is to halve the volume of waste produced by 2050, concerns all actors in the territory: citizens, companies, public authorities. What is bio-waste and why sort it? A bio-waste is a food waste (peelings, meat and fish remains, bread…) or a natural biodegradable waste that can be recovered in compost. In this law, the question of bio-waste management is raised. These wastes must be separated from the others since their burial in the absence of oxygen is favorable to the phenomenon of fermentation which releases methane into the atmosphere. However, the global warming power of methane is 25 times greater than that of CO2. It therefore plays an active role in global warming. It is therefore becoming urgent to make the most of our bio-waste. Incineration in the current treatment methods for food waste consists in particular of burning water, which may seem absurd. How to recycle bio-waste? Bio-waste can be recovered by different processes: compost spreading (if no prior composting, or on the spreading site it seems to me that it is forbidden). The spreading would also call for composting. methanization -> biogas production These reactions have the advantage of allowing the material to return to the ground. -> This is precisely the comparative advantage of composting VS methanization (biogas does not return to the ground). Some key dates in the management of bio-waste : 01/2012: the large producers of waste (120t/1500 L of edible oil per year) are committed to sorting biowaste and recycling it in appropriate channels. 01/2016: volume reduction to 10 t and 60L by 2025: every French person will have to have a solution for sorting food waste at source. 2. The creation of Restovalor Restovalor was created from the association of 3 companies: Azura, a waste collection company in Gironde which provides the material means. 3R concept company specialized in the destruction of paper. It works on the strategic part of Restovalor, namely market analysis and partnership. 10% environnement, a consulting company, is an investor in Restovalor. 3. The management of bio-waste by Restovalor Today, small producers of biowaste are not obliged to recover their fermenticide waste. As this constraint is not yet imposed on them, the recovery of bio-waste is currently an additional cost for these producers. Restovalor proposes a service allowing any producer of food waste to valorize it. Restovalor proposes a customized service dedicated to the recovery of food waste (biowaste) generated by the catering industry in Bordeaux Metropole and Gironde. The company offers specific containers, adapted collections and recycling of organic waste through methanization and composting. It invoices the collection according to the volume of waste and the frequency of collection. The company works with 3 types of customers the large-scale distribution which produces an important quantity of bio-waste.The communities (town halls, colleges, high schools…)The restaurant owners who produce as waste mainly bio-waste. Indeed, ⅔ of a restaurant owner’s trash can is composed of biowaste. The company collects conditioned bio-waste, meaning that this waste has been previously separated from the rest of the household waste by the customer. The company provides different types of containers that are adapted to the client’s biowaste production. Each container requires a specific collection: open bins are collected by trucks the garbage cans are emptied by dump trucks The buckets are collected by bicycle The collection of bio-waste is handled by Azura. This tailor-made solution allows us to collect more than 150 tons of biowaste every month. This bio-waste is taken to the only methanization center in the Bordeaux metropolitan area. After a deconditioning stage to remove impurities, the waste is incorporated into the methanizer to produce energy and compost. sustainable development approach Environemental benefits The management of bio-waste allows to fight against the carbon footprint caused by the fermentation resulting from the degradation of organic matter. It also reduces the amount of waste incinerated. Economic benefits This recovery loop allows the energy and agronomic potential to emerge through the collection of bio-waste from food and catering professionals. This system is adapted to all volumes of bio-waste: from small producers to the largest. Sources : [1] Ministère de la transition écologique Back to the encyclopedia Newsletter CirculAgronomie Subscribe Facebook Youtube Linkedin Instagram Legal information Copyright CirculAgronomie 2020

Cyfruileg

Cyfruileg donne une seconde vie aux fruits et légumes “moches” de la grande distribution en les transformant en jus, soupes et confitures.

Ovive

Ovive recovers shellfish waste from oyster farmers on the French Atlantic coast into animal feed, mainly for gallinaceans.