SOGAS

Sustainable supply

![]() SÉNÉGAL

SÉNÉGAL

Contact: contact@sogas.sn

Location: Dakar, Sénégal

Sector: End of life

Date of analysis: November 2016

Maturity of the project: lasting

Towards energy self-sufficiency by producing biogas from slaughterhouse waste.

Overview

The Dakar slaughterhouse is the largest slaughterhouse in Senegal. Managed by the Slaughterhouse Management Company of Senegal (SOGAS), to which it belongs, this slaughterhouse teems with thousands of micro-enterprises coming to recover the slaughtered and dismembered animals.

THECOGAS is a private company whose core business is the promotion of industrial biogas in Senegal and the sub-region. The Dakar abattoir has therefore acquired the industrial scale biogas technology of this private company and is making a perfect demonstration model to encourage other projects of the same type.

- Employees: 1

- 1500m3 of methane (CH4) produced daily

- 20 tons of recycled waste per day

- 70 m3 of recycled wastewater

- 50% of the energy needs of the slaughterhouse covered by the project

- Sustainable supply

- Recycling

Project operation

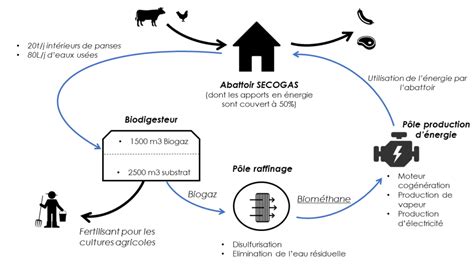

Methanation is an anaerobic process of degradation of organic matter. Every day, about 20 tons of interiors of rumen and 60 m3 of water are introduced into the biodigester.

The water comes only from the washing waters of the slaughterhouse. After a 40-day digestion process, two extremely valuable products are released: the digestate (solid and liquid fraction) and the biogas (gas fraction).

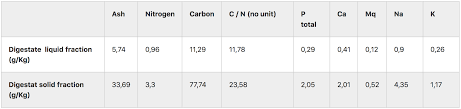

The digestate is the solid and liquid fraction that results from the anaerobic digestion process. It corresponds to 80% of the total mass of substrate (organic matter + water) introduced. This digestate is an excellent fertilizer for crops. Here are the results of digestate analyzes made by the Senegalese Institute of Agricultural Research.

The biogas produced is composed of 68% CH4, 25% CO2, 1.5% O2 and less than 200 ppm H2S. H2S is first chemically treated by blowing air into the digester, thus creating a redox reaction: 2 H2S + 2 02 >>> 2 H2O + 2 SO2. A desulfurizer composed of iron filings allows iron to fix the H2S and the residual water in the refining center.

The biomethane coming out of this refining pole is introduced into a cogeneration engine which makes it possible to produce electricity and water vapor and thus water. That cover a large part of the slaughterhouse’s needs.

sustainable approach

- Considerable reduction of pollution. Before all slaughterhouse waste was discharged into Hane Bay.

- Production of clean energy

- Production of a natural fertilizer that can substitute part of the chemical fertilizer for agriculture in the region.

- Reduction of the energy bill of the slaughterhouse

- Additional source of income through the sale of digestate to farmers in the region

- Source of efficient fertilization for soils

- Job creation

- Development of agriculture in the region: the company contributes to improving the standard of living of the local population

- Significant reduction of the health risk related to the treatment of slaughterhouse waste

Replicability & future perspectives

The Sogas / Thecogas project is perfectly reproducible. As a proof, many facilities for the treatment of organic waste by anaerobic digestion are being created around the world.

Several points must nevertheless be taken into account during the installation of an anaerobic digestion unit. It is important to size the plant according to the available supply in the region. Conducting a study of its deposit of waste and the maximum distance from which it is no longer advantageous to recover it is essential.

Finally, one of the limits of such a project lies in the sale of digestate as a fertilizer, which can sometimes cause problems of acceptance by society.