Arbiom

Industrial and Territorial Ecology

![]() FRANCE

FRANCE

Web : https://arbiom.com/

Contact : https://arbiom.com/contact/

Location: USA, France

Sector : Manufacture – Transformation

Date of creation : 1997 (previously named Biométhodes)

Date of analysis : July 2020

Maturity of the project : Industrial Demonstration Phase

To meet the world’s nutritional needs and respond to one of the major challenges of the 21st century, Arbiom has developed a solution for converting by-products from the wood industry into a food ingredient rich in complete proteins.

Overview

- As early as 2008, a biorefinery project, but to transform wood into biofuels

Arbiom, formerly Biométhodes, is a French company created in 1997 at the Génopole (a group of laboratories dedicated to genetic research) in Evry. The company first specialized in enzymes, developed in its industrial platform Optazyme. In 2008, in partnership with the American university Virginia Tech, Arbiom developed a technology for the pre-treatment of lignocellulosic biomass, validated by its American subsidiary Optafuel on a pilot scale. In 2015, the parent company became American, based in the Research Triangle Park in North Carolina, with the French subsidiary in charge of the demonstration program and the first commercial unit of the company.

- In 2015, a strategy redirected towards food production with the BioSkog

Initially, Arbiom biorefineries were used to produce second-generation sugars for “green chemistry” and biofuel applications. The drastic drop in the price of oil and the major food issues facing the world today have prompted Arbiom to redirect its applications to the buoyant agri-food sector, particularly proteins. Arbiom has therefore added a new technological brick to its lignocellulosic biomass fractionation process by optimizing a non-GMO yeast strain and a fermentation process for these yeasts that allows them to produce a large quantity of proteins of superior nutritional quality. Arbiom has thus developed Sylpro®, its first protein-rich ingredient obtained from wood.

- The demonstration program, an essential prerequisite for the construction of a commercial unit

The H2020 (BBI-JU) SylFeed Program

SylFeed is a 4-year project that will end in September 2021. Partially financed by Europe within the framework of a Horizon 2020 project for 10.9 M€, SylFeed aims at creating a new value chain between the wood industry and the aquaculture industry. The aim is to validate Arbiom’s technology (with technical partners) and product (with potential customers) on an industrial scale. The consortium, composed of 10 partners is coordinated by Arbiom, each partner bringing its own expertise in the value chain, from wood supply to the final customer, formulator of feed for aquaculture.

Initially, the demonstration program envisaged the construction of a demonstration unit in Golbey (Vosges). In 2019, the project has been reoriented towards the use of demonstration platforms in Belgium and the Netherlands, thus reducing investment, lowering operational risk and saving time.

The H2020 NextGen Proteins program

In 2019, Arbiom joined the European Nextgen Proteins program, partly funded by Europe, as a partner. This project, which brings together 21 partners, aims to compare various alternative protein sources (wood, insects, algae). The aim of the project is to compare these different sources of proteins for applications in animal feed and also in human food, thus supporting the potential of SylPro® in these different markets.

The next step: construction of a first commercial unit

The technological and commercial validation of Arbiom and its Sylpro® product will lead to the construction of the company’s first commercial unit, to be built in partnership with an upstream industrialist, which will allow the pooling of part of the facilities and secure the supply of raw materials.

- 30 employees in France and the United States

- A future high-protein product (> 60% protein)

- 7 times less CO2 emissions than soy concentrates

- Industrial and territorial ecology :

As a reminder, ADEME defines industrial and territorial ecology (EIT, or also industrial symbiosis), as the “inter-company mode of organization characterized by exchanges of flows or mutualization of needs. Industrial and territorial ecology aims at optimizing the resources on a territory, be it energy, water, materials, waste, but also equipment and expertise, through a systemic approach inspired by the functioning of natural ecosystems”.

Moreover, according to the International Energy Agency, biorefinery is the central pillar of the bioeconomy.

Arbiom is part of this approach through their biorefinery project in partnership with an industrialist. The result will be the pooling of equipment, water and energy flows, greater security of supply and diversification of outlets.

- Sustainable supply :

Wood is an abundant raw material in France, and represents a great potential for development. Arbiom therefore proposes a solution to optimize the exploitation of this resource, to offer a sustainable alternative to existing proteins (soybean, fishmeal). In fact, by bridging the gap between two sectors, they build a sustainable outlet for the wood sector and provide a sustainable source for the food protein sector.

Project operation

First of all, what is a biorefinery?

A biorefinery is a global technological system defined as a combination of physical, chemical and/or biological deconstruction, separation and functionalization technologies aimed at sustainably transforming biomass into intermediate or finished commercial products: food and feed, chemicals, materials and energy. In short, a biorefinery is a smarter, more sustainable plant that fits into its environment.

As presented in the history of the project, Arbiom’s competitive advantage comes mainly from the integration of a lignocellulosic biomass fractionation technology with an optimized fermentation process to produce a protein-rich ingredient. Armed with this technology and unique expertise, Arbiom’s goal is now to secure and develop the entire value chain, from wood to fork.

How is it possible to transform wood into food proteins?

Arbiom’s value chain is in theory quite simple. It involves deconstructing wood into cellulose molecules and then into fermentable sugars because wood is in fact partly composed of sugars. The sugars then serve as a medium for the growth of yeasts, optimized by Arbiom to adapt to the wood sugars and to produce a large quantity of proteins with high nutritional value.

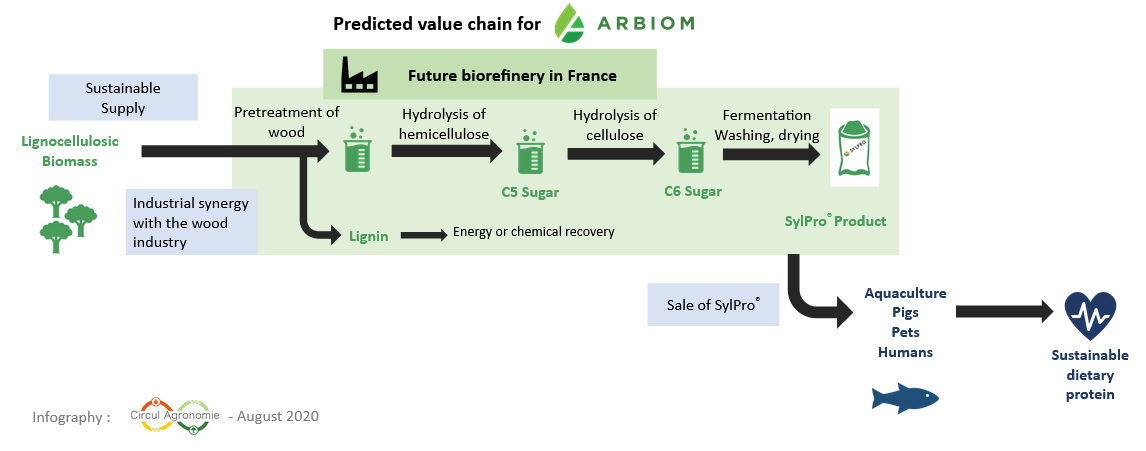

In fact, as you can see above, this process is built in several steps :

A pre-treatment of wood (industrial chips, sawmill off-cuts, etc.) with an acid attack to deconstruct the lignocellulosic biomass into lignin;

Enzymatic hydrolysis of hemicellulose to release C5 sugars;

Enzymatic hydrolysis of cellulose which releases type C6 sugars;

To this medium rich in sugars is added yeasts optimized and selected by Arbiom (non-GMO) which develop by fermentation;

The yeast-rich medium is then washed, dried, and packaged to give the final SylPro® product.

SylPro® is a high protein product (> 60% protein) with an amino acid profile (notably lysine, methionine, and threonine) and optimal digestibility for animal feed. It is therefore positioned as a real competitor to traditional protein sources (e.g. fish meal or soy protein concentrate), whose amino acid profiles are not complete. Moreover, it has significant environmental and economic advantages over other commercially available protein sources.

Such a product is achieved through the use of a yeast strain improved and optimized by Arbiom. Arbiom’s strain is already approved by American, Canadian and European authorities for feed and food applications. SylPro® represents a sustainable alternative to conventional protein sources, with a lower environmental impact (little soil and water is required for its manufacture).

Since 2018, large-scale in-house and potential customer tests have been carried out as part of the product’s commercial validation, which will enable the product to be launched on the market as early as 2021. The benefits of SylPro® have been rewarded by numerous awards: it is a natural, economical, traceable, sustainable product, a source of protein for both human and animal nutrition and thus a particularly innovative product.

sustainable approach

Numerous environmental benefits are to be noted for Arbiom’s future SylPro® product. In particular, the industrial synergy project will make it possible to reduce the product’s environmental impact (because production will be localized and because there will be minimal losses in the process). In the current context where 70% of dietary proteins are imported from abroad, SylPro® has significant benefits in terms of CO2 emissions (Arbiom has already demonstrated that their product is 7 times less CO2 emitting than a traditional alternative, soy concentrates), water use, energy use but also land use.

A Life Cycle Assessment of SylPro® is currently underway, which will enable the environmental benefits of the future product to be quantitatively justified. The results should appear by the end of 2020.

In spite of the many forests covering its territory, France is today suffering from a decline in the wood and paper industries, which are struggling to find an economic balance that will enable them to secure their historic activities. The timber industry now represents France’s second largest economic deficit after oil, and its players are faced with the need to find new economic models that are viable in the long term, notably by diversifying their activities and optimising the value of the by-products of their historical activities.

While contributing to the diversification of this declining sector, Arbiom’s proteins would be sold at a price substantially similar to the proteins for animal feed on the market, and would therefore be just as accessible.

Originally, the project was part of a worldwide demand for proteins. A 70% increase in the demand for protein is expected by 2050, and protein will therefore be the nutrient most in short supply in terms of quantity. The production of proteins from wood is very interesting from a social point of view because it allows to offer nutritionally complete and monetarily accessible proteins, without competing with food use or land use.

Moreover, the biorefinery would contribute to economic growth and the creation of sustainable jobs: increasing the income of biomass producers by diversifying their activities while securing jobs in the upstream industry (wood, paper mills, etc.).

Replicability & future developments

Is the Arbiom project profitable?

Although we were not able to estimate the production and operating costs of the biorefinery, we believe that Arbiom’s model is entirely profitable. Demand is real, with 4 target markets in which they intend to position themselves (piglet feed, fish, pet food and human food) are experiencing very strong growth, with, for example, an annual growth rate of 7.2% for fish feed expected between 2020 and 2025 to reach $71.6 billion in 2025.

In this case, why is it so complicated to build a biorefinery?

In France, apart from the Pomacle-Bazancourt biorefinery (production of sugar, ethanol and other co-products from beet, wheat and alfalfa), and the La Mède biorefinery (biofuel from corn), there are no other industrial biorefineries in France despite a growing demand for bio-based products. The construction of an industrial biorefinery is very expensive and many projects fail at the industrial development stage. Beyond technical feasibility, it is particularly important to secure financing by using several levers:

- Securing partnerships with existing industrial sites in order to pool the use of already available utilities. Industrial and territorial ecology is therefore a real asset for biorefinery projects!

- Reduce its CAPEX, i.e. the total investment of the project.

- Combine public and private investment, with a strong incentive from public aid (an investor unblocks and encourages other investors).

- Securing product outlets, for example with contractualized volumes.

The technological and commercial validation of Arbiom and its Sylpro® product will lead to the construction of the company’s first commercial unit, to be built in partnership with an upstream industrialist, which will allow the pooling of part of the facilities and secure the supply of raw materials.

It is clear that in the context of the energy transition and the bioeconomy, the biorefinery concept will develop and play an increasing role in the transformation of biomass co-products into bio-sourced products.

We are delighted to have been able to interview Arbiom employees and analyze their project which proposes an innovative solution for sustainable food. The success of a biorefinery is based on long-term work, and studying this company has given us a better understanding of the brakes and levers of such a project.

In our opinion, biorefineries embody the model to be followed for today’s and tomorrow’s plants in the field of vegetal products, and are perfect examples of the “Industrial and Territorial Ecology” pillar of the Circular Economy.

For the time being, Arbiom’s products are not yet on the market, but we hope from the bottom of our hearts that their project will come to fruition, and that many other sustainable biorefineries will eventually see the light of day in France and around the world.